I was brought into the program after early onboarding work had already happened with central resources and the contract manufacturer.

No rewind button.

No ability to go redo the initial visits.

My role was to serve as the cross-functional liaison between the internal manufacturing site and central teams at headquarters—engineering, R&D, and program leadership—keeping the work aligned as we moved production in-house.

The moment I knew we had a problem: qualification exposed persistent fill weight variability—and the contract manufacturer was still the only source of supply. Here’s how we held standards, protected supply, and earned readiness gate by gate.

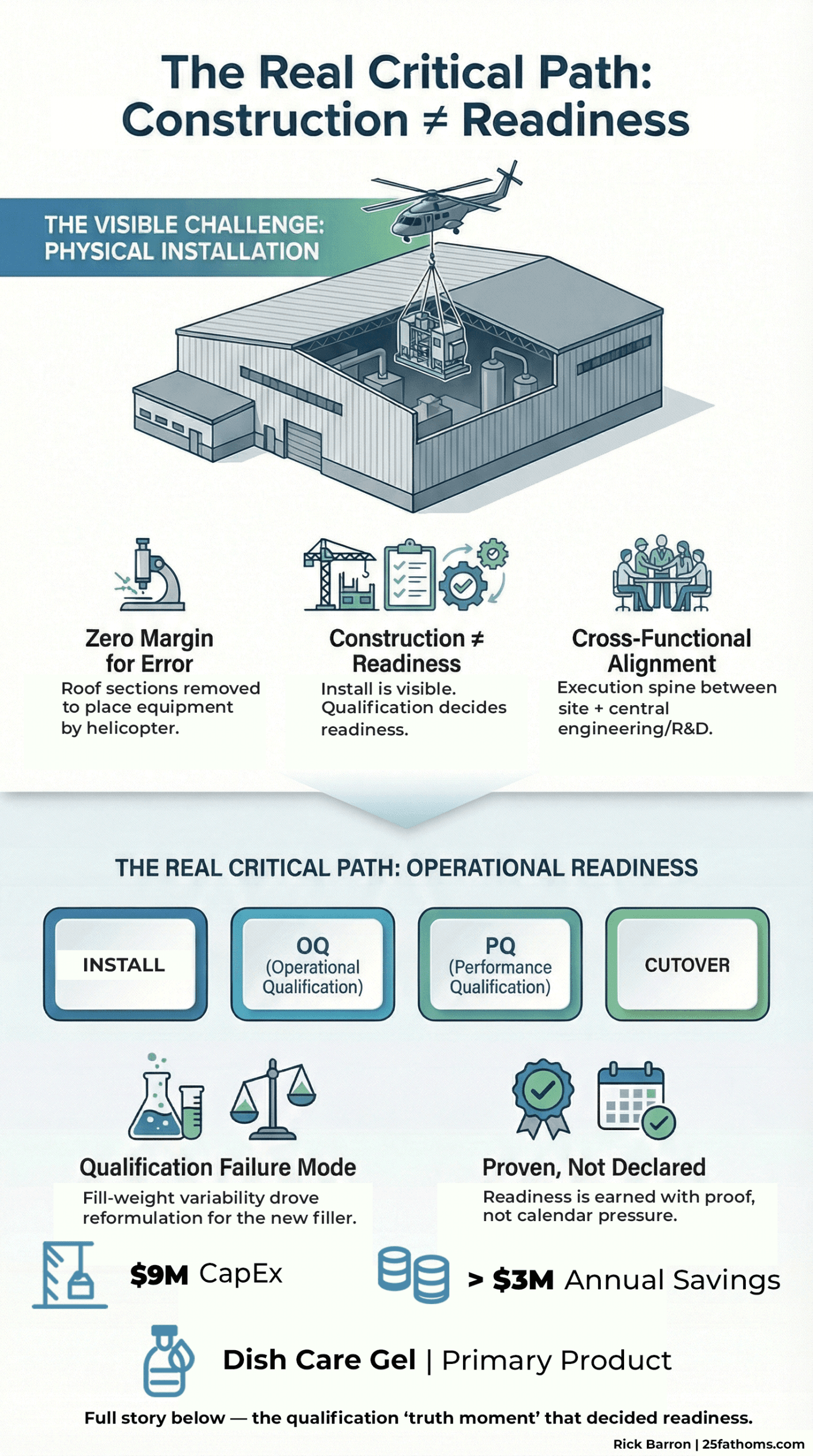

A real-world transfer where qualification—not construction—decided readiness.

Outcomes

- Migrated Dish Care Gel from a contract manufacturer to an internal site with $9M CapEx and >$3M annual savings

- Executed a zero-margin installation plan—roof sections removed and equipment placed by helicopter due to extreme space constraints

- Implemented new filling technology and synchronized a reformulation to enable stable operation

- Protected supply while qualifying the new process—holding PQ standards while stabilizing fill weight variability

- Supported clean closeout at the contract manufacturer, including fixed asset identification and disposition

The problem

The internal manufacturing site was dated, crowded, and short on space.

The program required adding a new manufacturing operation into an environment that had no margin for additional equipment.

On top of the relocation, the filling operation was changing.

A new filling technology was being installed—requiring the product to be reformulated so it would run properly on the new filler.

So the job wasn’t simply “move a line.”

It was: install + new technology + reformulation + qualification—without losing supply.

What made it hard

There were three constraints at the same time:

- Space reality: The fit was so tight the installation plan included removing roof sections and using helicopters to drop equipment into place.

- Process change: New filler technology required a reformulation to run correctly—two moving targets at once.

- Supply risk: While qualification struggled, the contract manufacturer remained the only source of supply.

Then the critical path showed up where it usually does:

qualification.

The failure mode was clear and painful: fill weight variability.

It wasn’t an annoyance.

It was the readiness signal.

What I did

I approached the work the way I’ve learned to approach transfers like this:

assume the critical path is readiness.

Then build the gates and discipline to prove it.

1) I treated readiness as a gate system, not a declaration.

We aligned around the gates that mattered—Install → OQ → PQ → Cutover—and kept decisions tied to evidence, not calendar pressure.

2) I kept cross-functional alignment tight as complexity piled up.

My primary value was keeping the internal site and central teams synchronized—engineering, R&D, and program leadership—so the work didn’t fragment into local optimizations and late surprises.

3) I held PQ standards when the process wouldn’t cooperate.

Fill weight variability became the wall.

The temptation in moments like that is to “move on” and assume it will settle out later.

We didn’t do that.

We kept qualification honest—because that’s what protects long-term performance and avoids a future quality/supply headache.

4) I protected supply while qualification stabilized.

Because the contract manufacturer was still the only source of supply, we had to manage qualification without triggering a supply gap.

That required discipline, pacing, and clear decision-making—especially under pressure.

5) I supported clean closeout at the contract manufacturer.

Transfers don’t end when the new site starts running.

I also supported fixed asset identification and proper disposition at the contract manufacturer to close the loop cleanly and correctly.

Construction gets equipment into the building.

Qualification earns the right to ship.

Readiness isn’t declared. It’s proven—gate by gate—when the process is under load and still holds the standard.

If you’re leading a CM → internal transfer, here’s what I’ve learned to insist on early:

- Readiness gates that prevent “calendar-driven readiness”

- PQ discipline when the process won’t cooperate

- Supply protection while the new process earns stability

- Cross-functional clarity so decisions don’t drift

Do that, and the dramatic stuff (like dropping equipment through a roof) becomes just part of the story—not the thing that decides the outcome.

If you’ve lived a qualification “truth moment” where the process fought you harder than the plan predicted, I’d love to compare notes — what was your failure mode?

0 Comments